Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

PVC Sheet vs Other Plastic Sheets: Performance Comparison and Selection Guide

Plastic sheet materials, as a fundamental industrial material, play an indispensable role in contemporary industrial production and social life. From food packaging in daily life to protective films for high-end electronic products, from building decoration materials to medical device components, plastic sheet materials, with their lightweight, durability, and ease of processing, have permeated every field of modern industry. With the continuous advancement of materials science, various plastic sheet materials such as PVC, PET, PP, PS, etc., each with their own characteristics, provide diverse options for different application scenarios.

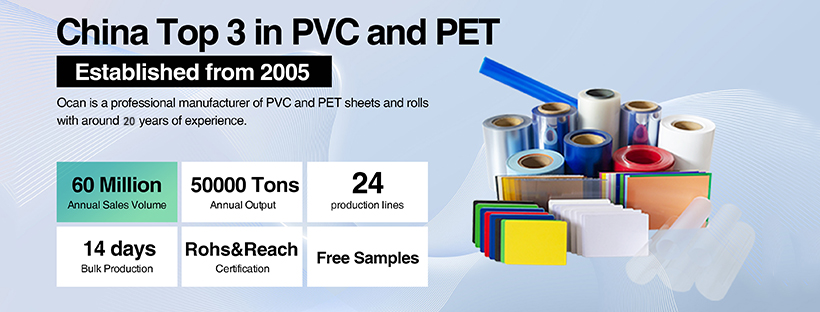

Among all the plastic sheet materials, PVC sheet materials have long occupied an important market share due to their excellent comprehensive performance and relatively low cost. Suzhou Ocan Polymer Materials Co., Ltd. is a company specializing in the research, production, and sales of high-performance polymer materials. It is one of the largest PVC sheet manufacturers in East China. Its products cover eight major series and over 100 varieties of PVC, PET, PC, etc. This article compares the PVC sheet materials produced by Suzhou Ocan Polymer Materials Co., Ltd. with other plastic sheet materials and provides a guide for choosing plastic sheet materials.

1 Overview of Main Plastic Sheet Materials

1.1 Characteristics and Applications of PVC Sheets

PVC is one of the earliest plastic varieties to be industrially produced, with its history dating back to the 1930s. PVC materials possess excellent chemical resistance, flame retardancy, and mechanical strength. By adjusting the formula, products with different properties ranging from hard to soft can be produced. Depending on the content of plasticizers, PVC sheets can be classified into rigid PVC and soft PVC, and this flexibility makes their application scope extremely wide.

Rigid PVC sheets/rolls have high rigidity and dimensional stability, with a thickness range typically between 0.15-5mm. They are suitable for applications such as signs, display stands, and construction templates that require structural strength. Soft PVC, due to its flexibility and ease of processing, is often used in packaging and medical catheters. PVC materials can also be produced with various special effects such as color, frosted, matte, and anti-fog by adding different pigments and surface treatment processes, meeting the decorative and functional requirements of different industries.

1.2 Brief Introduction to Other Common Plastic Sheets

Apart from PVC, various other plastic sheets are widely used in modern industry, each with its own unique performance characteristics and application advantages:

Polypropylene (PP) sheets are known for their light weight, good chemical resistance, and low cost. They are one of the preferred materials in the field of food packaging. PP shows good tolerance to most chemical reagents and complies with safety standards for food contact materials, and are commonly used in disposable tableware, food containers, and other products.

Polystyrene (PS) sheets have high rigidity and excellent electrical insulation properties, but are relatively brittle and are mainly used in disposable containers and packaging for electronic products in short-term scenarios. Through the foaming process, EPS (foamed polystyrene) can be produced, which has excellent buffering performance and is widely used in the packaging of precision instruments.

Polycarbonate (PC) sheets are renowned for their outstanding impact resistance. Their impact strength can be more than 10 times that of PVC, and are often used in safety protection masks, riot shields, and other scenarios requiring high impact resistance. At the same time, PC materials also have good thermal stability, with a heat deformation temperature of over 130°C.

ABS sheets combine multiple advantages such as strength, toughness, and surface smoothness, and are ideal choices for electronic product casings, automotive interiors, and other applications. By adjusting the proportions of the three monomers, different performance characteristics of ABS materials can be produced to meet diverse industrial needs.

2 Comparative Analysis of Key Performance Parameters

2.1 Comparison of Mechanical Properties

Mechanical properties are one of the primary considerations when choosing plastic sheet materials, as they directly affect the performance and lifespan of the product. From the perspective of tensile strength, PET and PC perform the best, reaching 55-75 MPa and 60-70 MPa respectively, making them suitable for applications that require significant tensile stress. The tensile strength of PVC is in the middle, approximately 40-60 MPa, but through formulation optimization and processing process improvement, its mechanical properties can be further enhanced.

Bending modulus reflects the rigidity of the material. In this indicator, PS performs the best, reaching 3-3.5 GPa, suitable for thin-walled products that require high rigidity. The bending modulus of PVC is 2-4 GPa, at a medium level, ensuring sufficient rigidity while maintaining a certain degree of toughness.

In terms of impact strength, PC leads with an excellent performance of 60-80 kJ/m², being the preferred choice for manufacturing impact-resistant products. The impact strength of ordinary PVC is approximately 5-30 kJ/m², but by adding impact modifiers, this performance can be significantly improved.

2.2 Thermal Performance Comparison

In terms of moulding performance, both PVC and PET are suitable for vacuum moulding, but PET requires a higher forming temperature (usually 20-30°C higher than PVC). The thermal forming performance of PETG material is the best, as it can be formed into complex shapes at relatively lower temperatures, significantly reducing processing difficulty and energy consumption.

Flammability is a key requirement in many application scenarios. PVC itself has excellent flammability and can meet the UL94 V0 standard without adding flame retardants, making it an ideal choice for fields such as construction and electronics that have strict fire safety requirements.

2.3 Comparison of Chemical Stability

Chemical stability determines the durability of plastic sheeting in various environments. PVC has excellent tolerance to acids, alkalis, and alcohols, making it suitable for corrosion-resistant environments such as the linings of chemical equipment and laboratory countertops. However, its resistance to some organic solvents (such as ketones and esters) is relatively weak, and it may undergo swelling or stress cracking in the presence of these solvents.

PET has excellent oil resistance and does not react with food components, making it an ideal material for packaging of edible oils, seasonings, etc. PP is resistant to almost all organic solvents, but has poor resistance to oxidizing acids (such as concentrated sulfuric acid and concentrated nitric acid), and is prone to aging and degradation in a strongly oxidizing environment.

2.4 Comparison of Optical Properties

Optical performance is of vital importance for applications such as packaging and display. Transparent PET has the best optical transparency (>90%) and low haze, making it the preferred material for high-end cosmetic packaging and electronic product windows. The transparency of PVC transparent materials is approximately 85-88%, slightly inferior to PET, but it can approach the level of PET through optimized formulation and processing techniques.

In terms of surface effects, PVC materials can achieve various special effects through processes such as embossing and coating. Matte PVC, through the design of surface microstructures, produces a soft light scattering effect, which protects privacy while not affecting lighting. Colorful PVC sheets offer a wide range of color options and have good color stability, not prone to fading, making them suitable for long-term outdoor use.

3 Application Scenario Selection Guide

3.1 Printing and Signage Applications

In screen printing and offset printing applications, the selection of materials directly affects the printing quality and the lifespan of the products. PVC sheet materials have become the preferred choice for signage production due to their excellent ink adhesion and dimensional stability. The PVC surface has an appropriate polarity and good compatibility with most inks, resulting in clear and full printed patterns and a low risk of ink diffusion.

Color PVC sheet materials are particularly suitable for high-end signage production. Their base material has uniform and stable colors, and even if the surface is worn, the underlying color will not be exposed, ensuring the long-term aesthetic appearance of the signage. Additionally, PVC materials are easy to cut, engrave, and thermoform, allowing for the creation of various three-dimensional signs and shaped text, meeting the needs of creative design.

For outdoor signage, the weather resistance of PVC is particularly important. High-quality PVC sheet materials are added with UV stabilizers and antioxidants, which can resist the erosion of outdoor environments such as sunlight, rain, and temperature changes, maintaining the long-term stability of color and performance. In contrast, materials like ABS are prone to yellowing and brittleness in the outdoor environment, with shorter lifespans.

3.2 Selection of Applications in the Packaging Field

Food packaging has extremely high requirements for the safety of materials. PET and PP are chosen as the first options due to their excellent food safety properties. PET has high chemical inertness and does not react with food components or release harmful substances. Its high transparency allows for a clear display of the contents of the packaging. PP, on the other hand, is widely used in various food packaging due to its low cost and good heat-sealing performance.

Electronics packaging needs to consider protection, anti-static properties, and environmental requirements comprehensively. Anti-static PVC effectively prevents static accumulation by adding anti-static agents to the formula, protecting sensitive electronic components. At the same time, the buffering performance and strength of PVC can well protect the product from shocks and vibrations during transportation.

Luxury packaging places more emphasis on texture and brand image. Matte PVC and metal-effect PVC can provide an upscale visual experience. These materials, through special surface treatment processes, produce visual effects similar to those of high-end materials such as metal and ceramics, while maintaining the lightweight and easy-processing characteristics of plastic, significantly enhancing the product's value.

3.3 Selection of Building Decoration Materials

Building partitions and decorative panels have strict requirements for the fire resistance of materials. The inherent flame-retardant property of PVC gives it a significant advantage in this field. After the fire source is removed, PVC materials will self-extinguish and will not contribute to the spread of the fire. Moreover, when burning, they produce relatively less smoke, thereby enhancing the safety performance of buildings.

Weather resistance is another key indicator for outdoor building materials. PVC with added UV stabilizers can be exposed to sunlight for a long time without significant aging, maintaining the stability of color and mechanical properties. In contrast, some weather-resistant materials such as ordinary ABS may show discoloration and brittleness after being used outdoors for a period of time.

The convenience of cleaning and maintenance is also a consideration factor for building materials. The surface of PVC is smooth and dense, and it is not prone to adsorb dust and stains. Routine cleaning only requires wiping with a damp cloth. Some special formulations of PVC also have antibacterial functions, inhibiting the growth of bacteria and mold, and are particularly suitable for places with high hygiene requirements such as hospitals and schools.

4 Considerations for Sustainable Development

4.1 Comparative Analysis of Recyclability

With the increasing awareness of environmental protection, the recyclability of materials has become an important selection criterion. The recycling system of PET is the most complete. It can be recycled multiple times through physical or chemical methods, and the performance of recycled PET does not deteriorate significantly, making it suitable for application fields with high environmental requirements. Currently, the recycling rate of PET bottle pieces has reached over 90% in many countries.

PVC can theoretically be recycled, but it faces more challenges in practice. PVC requires a specialized recycling processing procedure, and it is difficult to separate PVC waste mixed with different additives and colors, which affects the quality of recycled materials. However, through improving sorting technologies and developing new compatibilizers, the recycling utilization rate of PVC is gradually increasing.

4.2 Environmentally Friendly Innovation Trend

To comply with increasingly stringent environmental regulations, the plastic industry is actively promoting material innovation. The development of lead-free stabilizers in PVC formulations has addressed the environmental risks associated with lead salts in traditional PVC. By adopting environmentally friendly stabilizing systems such as calcium and zinc, the environmental risks have been significantly reduced without compromising performance.

Products that meet RoHS and REACH standards have become the mainstream in the market. These standards strictly limit the use of harmful substances, prompting enterprises to develop cleaner production processes. Through optimized formula design, modern PVC products can now fully meet the requirements of these international environmental protection directives.

Optimizing production processes is also an important way to reduce the environmental footprint. By improving extrusion processes, adopting energy-saving equipment, and utilizing waste heat technologies, the energy consumption and emissions in plastic sheet production have been significantly reduced. Some leading enterprises have also established closed-loop water recycling systems to achieve zero discharge of production wastewater.

5 Conclusion

After the series of comparative analyses mentioned above, PVC sheet materials have obvious advantages in terms of comprehensive performance, processing convenience, and cost-effectiveness, and are particularly suitable for applications such as signage, architectural decoration, and industrial accessories. Their excellent flame retardancy, weather resistance, and mechanical properties, combined with relatively low costs, make them an ideal choice for many scenarios.

Suzhou Ocan Polymer Materials, as a professional producer of PVC sheet materials, has a rich product line and profound technical accumulation, and can provide full-chain services from technical consultation to after-sales support. Its quality and environmental management system certified by ISO9001 and ISO14001 ensures the consistency and reliability of the products, and it is a trustworthy partner.