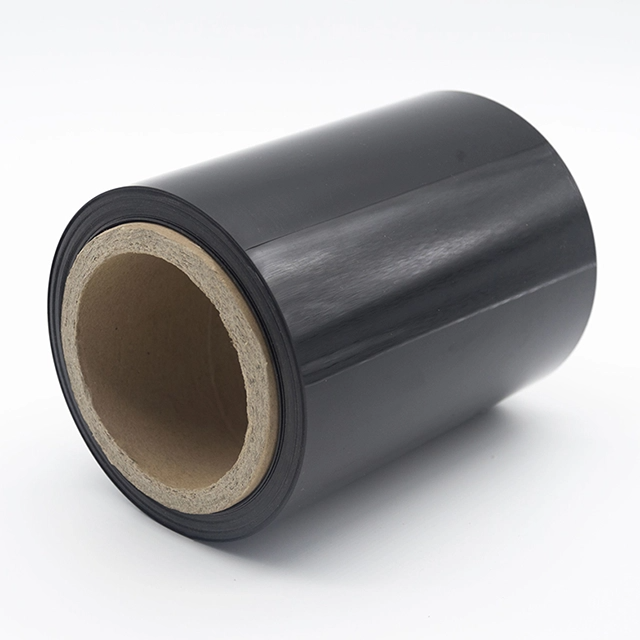

Black PVC roll is a versatile and widely used material in industrial, commercial, and residential applications. Made from polyvinyl chloride (PVC), these rolls are known for their strength, durability, flexibility, and chemical resistance. The black coloring not only provides an aesthetic finish but also enhances UV resistance, making it suitable for outdoor and indoor environments. Understanding what black PVC roll is, its applications, and benefits can help businesses, contractors, and DIY enthusiasts make more informed decisions when selecting materials for specific projects.

Black PVC roll is manufactured from polyvinyl chloride resin, mixed with stabilizers, plasticizers, and pigments. The addition of black pigment enhances its protective properties against sunlight and heat degradation. Unlike transparent or lighter-colored PVC, black PVC roll offers greater UV stability and prevents material breakdown when exposed to outdoor conditions. The flexibility of the material is adjusted by altering the amount of plasticizer, making it either rigid or highly flexible depending on its intended use.

Key properties include:

High tensile strength

Resistance to abrasion

Water and chemical resistance

UV protection due to black pigmentation

There are several variations of black PVC roll designed for different industries and purposes. Choosing the right type depends on whether the application requires flexibility, thickness, or specific resistance properties.

| Type of Black PVC Roll | Description | Common Applications |

|---|---|---|

| Flexible Black PVC Roll | Soft and bendable, with high adaptability | Curtains, insulation, protective covers |

| Rigid Black PVC Roll | Harder structure, retains shape | Signage, wall cladding, construction panels |

| Industrial Black PVC Roll | Enhanced thickness and durability | Flooring, conveyor belts, heavy-duty covers |

| Electrical Grade PVC Roll | Insulated and flame-retardant | Cable insulation, electrical housings |

Black PVC roll is used across multiple sectors because of its adaptability. In industrial settings, it is commonly employed as protective coverings, flooring materials, and conveyor belt surfaces. Construction professionals use it for waterproofing membranes, cladding, and temporary protective barriers. In agriculture, black PVC roll is applied for pond liners, greenhouse covers, and irrigation systems. Additionally, its chemical resistance makes it suitable for laboratories and factories where exposure to solvents or acids is common.

Main application areas include:

Industrial flooring and surface protection

Insulation for electrical cables

Waterproofing in construction

Protective barriers in agriculture

Packaging and sealing applications

The widespread adoption of black PVC roll is largely due to its practical benefits. Its versatility allows it to replace more expensive materials without sacrificing performance. Compared to rubber, leather, or certain metals, black PVC roll offers a lightweight yet durable alternative.

Advantages include:

Durability: Long-lasting performance under stress and exposure.

Cost-effectiveness: Lower cost than alternative materials.

Chemical resistance: Withstands oils, acids, and solvents.

Easy installation: Can be cut, shaped, or heat-welded as needed.

UV resistance: Enhanced outdoor durability due to black pigmentation.

When selecting a material for industrial or commercial use, understanding how black PVC roll compares to alternatives helps decision-making.

| Material | Strengths | Limitations Compared to Black PVC Roll |

| Rubber | Flexible, good for sealing | Higher cost, less chemical resistance |

| Polyethylene (PE) | Lightweight, waterproof | Lower UV resistance, less durability |

| Leather | Aesthetic, flexible | Expensive, less durable in industrial use |

| Black PVC Roll | Durable, versatile, chemical resistant | May be heavier in thicker grades |

This comparison highlights how black PVC roll balances affordability, durability, and versatility better than most alternatives.

Each industry applies black PVC roll differently depending on operational needs. For example:

Construction: Used for waterproofing foundations, temporary floor protection, and roofing membranes.

Automotive: Applied as seat backing, insulation, and protective mats.

Agriculture: Widely used in pond liners, greenhouse film, and silage covers.

Electrical: Provides insulation for wires and cables, offering flame resistance.

Packaging: Ensures durable, moisture-resistant protective wrapping.

By adapting to various demands, black PVC roll demonstrates its importance across industries.

Selecting the right black PVC roll requires considering factors such as thickness, flexibility, environmental exposure, and industry compliance standards. Buyers should evaluate whether the roll will be exposed to harsh weather, chemicals, or heavy mechanical wear. Additionally, confirming compliance with safety certifications (e.g., flame retardancy for electrical applications) is crucial for proper use.

Checklist for choosing Black PVC Roll:

Application purpose (industrial, electrical, agricultural)

Required thickness and durability

Indoor vs. outdoor use

Resistance to UV, chemicals, or abrasion

Compliance with industry standards

To maximize the lifespan of black PVC roll, proper maintenance is essential. Regular cleaning with mild detergents prevents buildup of dirt or chemicals that could degrade the surface. Avoiding sharp mechanical damage ensures longer usability. When installed correctly and maintained properly, black PVC roll can last for years, even in demanding industrial environments. Storage should be in cool, dry areas away from direct sunlight to prevent unnecessary degradation before use.

Black PVC roll is a durable, flexible, and cost-effective material that serves a broad spectrum of industries. From construction and agriculture to automotive and electrical applications, its adaptability makes it an indispensable resource. The combination of chemical resistance, UV stability, and ease of installation ensures that black PVC roll remains a go-to choice for businesses and individuals seeking reliable performance.

1. What is a black PVC roll made of?

It is made of polyvinyl chloride resin with added stabilizers, plasticizers, and black pigments for durability and UV resistance.

2. Where can black PVC roll be used?

It is used in construction, agriculture, automotive, electrical insulation, and packaging industries.

3. Why is the roll black instead of transparent?

The black pigment provides additional UV stability, making it better suited for outdoor use.

4. How long does black PVC roll last?

With proper use and maintenance, it can last several years, depending on environmental conditions and application.

5. Is black PVC roll environmentally friendly?

While PVC is not biodegradable, it can be recycled and reused, reducing its environmental impact compared to single-use plastics.