Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

Choosing the best white PVC roll for your project starts with understanding your needs. You must match the right vinyl type to your application. Many industries rely on vinyl for its versatility and durability:

Healthcare uses vinyl for single-use medical items and containers.

Automotive sectors prefer white PVC roll for seat coverings, sun visors, and interior panels.

Electronics depend on vinyl for cable insulation and protection.

Construction applies white PVC roll in waterproofing membranes and window frames.

You should check for moisture resistance, adhesive compatibility, and environmental durability. Avoid selecting vinyl without considering these factors.

Identify your project needs first, including durability, flexibility, appearance, and environment, to choose the right white PVC roll.

Check material properties like thickness, moisture resistance, and UV protection to ensure long-lasting performance.

Decide between rigid and flexible PVC based on whether your project needs strength or bendability.

Choose permanent adhesive vinyl for strong, weather-resistant bonds and removable vinyl for temporary uses.

Maintain your white PVC roll with regular cleaning and UV protection to keep its durability and vibrant appearance.

When you select a white PVC roll, you must start by identifying the specific needs of your project. Each application has unique demands, and matching the right material to your environment ensures long-term performance and safety. Here are some key project requirements to consider:

Durability: Outdoor projects require materials that resist UV rays and weathering. White PVC rolls with UV stabilizers and protective coatings prevent degradation and extend lifespan.

Cost-effectiveness: You should look at both the initial purchase price and the long-term maintenance costs. White PVC roll offers a balance between affordability and durability, making it a popular choice for many industries.

Flexibility and Workability: If your project involves complex shapes or frequent adjustments, choose a white PVC roll that is easy to cut and shape to your exact specifications.

Aesthetic Needs: Consider the color, finish, and printability. For projects where appearance matters, such as displays or signage, select a roll with a smooth, bright surface.

Environmental Impact: Sustainability and recyclability matter. Many white PVC rolls now include additives for UV resistance and antimicrobial properties, and recycling rates are increasing.

Application Environment: Think about temperature, humidity, sunlight, and microbial exposure. For example, construction projects in humid or sunny areas benefit from PVC’s moisture and UV resistance.

Tip: Always prototype and consult with experts to ensure the material fits your project before committing to large orders.

If you plan to use a white PVC roll for helmet manufacturing, you need to focus on durability, safety, and appearance. White PVC rolls provide excellent impact resistance and can be formed into smooth, attractive shells. However, for safety-critical applications like helmets, you must check that the material meets industry safety standards. While PVC offers good mechanical strength and is easy to fabricate, some helmet designs may require additional reinforcement or specialized polymers for maximum protection. Always verify the specifications and test prototypes before mass production.

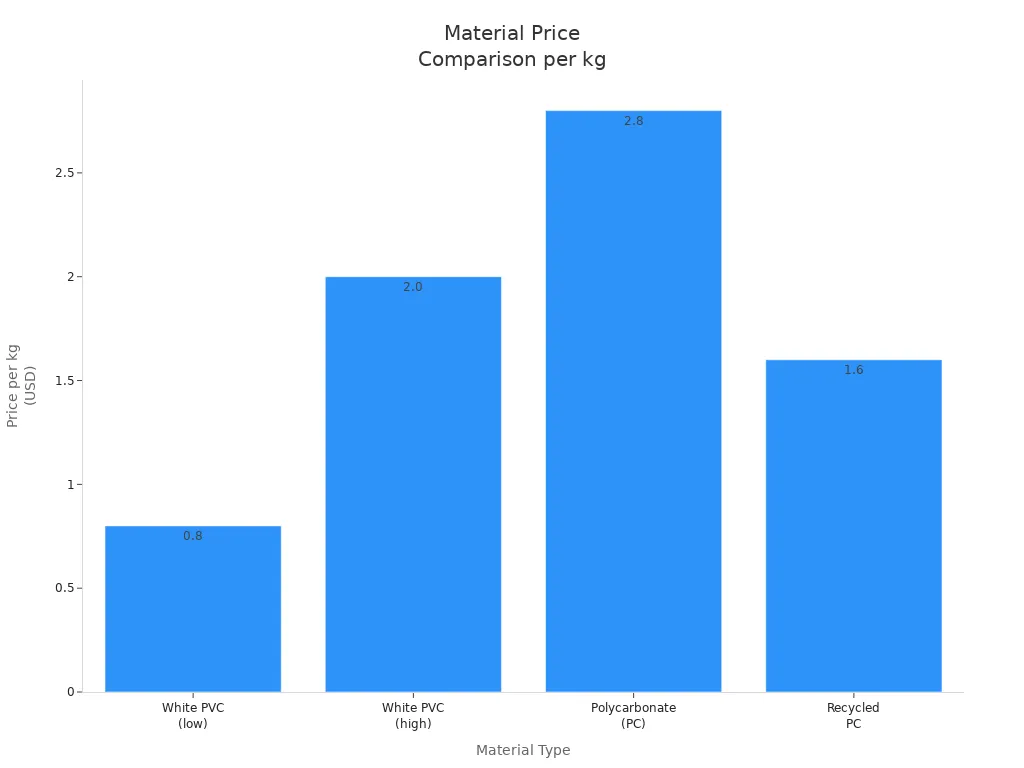

When you compare white PVC roll to alternative materials, you will find it is more economical and widely available. For example:

Material | Virgin Material Price (per kg) | Notes on Availability and Use |

|---|---|---|

White PVC (UPVC) | $0.80 - $2.00 | Widely available, interchangeable sources |

Polycarbonate (PC) | ~$2.80 | Specialist, higher cost, lower volume |

Recycled PC | ~$1.60 | Consistent supply chain required |

White PVC roll stands out for its balance of cost, durability, and versatility. You can select the right thickness, finish, and size to fit your project, ensuring both performance and value.

When you choose vinyl for your project, you must decide between rigid and flexible options. Each type has unique properties that affect how you use them. Rigid white PVC roll contains less plasticizer, which makes it stiff and strong. Flexible vinyl includes more plasticizer, giving it a soft and bendable feel. You can see the main differences in the table below:

Aspect | Flexible PVC Film | Semi-Rigid (Closer to Rigid) PVC Film |

|---|---|---|

Composition | Contains plasticizers for pliability | Less plasticizer, more stiffness |

Flexibility | Highly flexible and soft | Moderately flexible, sturdier |

Impact Resistance | Good under bending and torsion | Better impact and abrasion resistance |

Typical Applications | Hoses, inflatable products, coverings | Packaging, automotive interiors, construction |

Chemical Resistance | Excellent | Excellent |

Durability | Durable under flexing | Enhanced physical resistance |

Environmental/Health | Plasticizer content affects safety | Lower plasticizer content, regulated |

You should use rigid white PVC roll when you need high durability and structural strength. It works best for building projects, underground piping, electrical conduits, and static installations. Rigid vinyl resists weathering, corrosion, and UV radiation, making it ideal for outdoor and heavy-duty environments. Flexible vinyl fits projects that need easy installation and movement, such as irrigation systems or plumbing with curves.

Tip: Select rigid vinyl for long-term, maintenance-free service in harsh conditions. Choose flexible vinyl for projects that require bending or vibration resistance.

You may wonder how foam board compares to white plastic sheeting. Foam board is lightweight and best for short-term indoor signs. It has a foam core sandwiched between paper or plastic layers. White plastic sheeting, especially expanded PVC foam board, is more rigid and durable. It resists moisture, chemicals, and UV rays, making it suitable for both indoor and outdoor use.

Feature | Foam Board | White Foam PVC Roll |

|---|---|---|

Structure | Foam core with paper/plastic facers | Foamed PVC resin, porous, varying density |

Rigidity & Density | Lightweight, less dense | Denser, more rigid |

Typical Thickness | 0.125 to 3 inches | Varies by density |

Durability | Short-term indoor use | Medium-term indoor/outdoor use |

Common Use Cases | Displays, mounting, framing | Signage, displays, model making |

Cutting & Processing | Easy to cut, not for drilling | Requires power tools for high density |

Water Resistance | Some grades water resistant | Better durability and resistance |

If you want to buy white plastic sheeting for outdoor signs, wall panels, or office furniture, expanded PVC foam board is the best choice. It supports high-quality printing and lasts longer in harsh environments. Foam board works well for indoor displays, framing, and mounting, but it does not handle outdoor exposure. When you buy white plastic sheeting, you get a material that resists flame, moisture, and chemicals, making it perfect for demanding projects. Vinyl sheeting also offers smooth surfaces for vibrant graphics and easy cleaning.

Note: Always match your vinyl choice to your project’s environment and expected lifespan. White adhesive vinyl and white plastic sheeting provide versatile solutions for both indoor and outdoor applications.

When you choose adhesive vinyl material for your white PVC roll project, you need to decide between permanent and removable options. Permanent adhesive vinyl gives you a strong, long-lasting bond. This type of vinyl is thicker, usually around 20-25 microns, and works well for outdoor signs, vehicle decals, and surfaces exposed to weather. You can rely on permanent adhesive vinyl to stick to wood, metal, and textured materials. It resists heat, moisture, and UV rays, making it ideal for demanding environments.

Permanent adhesive vinyl lasts 3-5 years outdoors. You may find it difficult to remove, and it can leave residue or damage the surface. If you want your graphics or labels to stay in place for a long time, permanent adhesive vinyl is the best choice. Most white adhesive vinyl rolls use calendered grade films with a permanent acrylic pressure-sensitive adhesive. These rolls accept many types of inks and provide a smooth, bright finish for clear graphics.

Tip: Use permanent adhesive vinyl for projects that need durability and weather resistance, such as outdoor signage or equipment labels.

Selecting the right adhesive for your white adhesive vinyl is important for a successful project. You should consider the surface material, environmental exposure, and how long you want the label or graphic to last. Permanent adhesives work best for harsh conditions, including moisture, heat, and cold. Removable adhesive vinyl is better for temporary uses, such as short-term promotions or decorations, because it peels off cleanly without leaving residue.

You must also check for compatibility issues. Smooth or contaminated PVC surfaces can cause adhesive failure. Flexible vinyl contains plasticizers that may migrate and weaken the bond with some materials, like rubberized asphalt or old PVC roofs. To avoid problems, clean and roughen the surface before applying adhesive vinyl material. For flexible PVC, use a barrier if it will touch incompatible surfaces.

Aspect | Permanent Adhesive Vinyl | Removable Adhesive Vinyl |

|---|---|---|

Bonding Strength | Strong, long-lasting bond | Light bond, easy removal |

Longevity | 3-5 years outdoors | 1-2 years indoors |

Removal | May leave residue or damage | Peels off cleanly |

Best Use | Outdoor signs, vehicles, equipment | Temporary labels, indoor promotions |

Note: Always test your adhesive vinyl material on a small area of your white PVC roll before full application. This helps you avoid costly mistakes and ensures the best results.

When you select vinyl for your project, you want materials that last. White PVC roll offers exceptional durability in both indoor and outdoor environments. High-quality PVC tarpaulins and foam boards used outdoors typically last between 5 and 10 years. You can extend this lifespan with regular cleaning, timely repairs, and UV-resistant coatings. Built-in features like water and mildew resistance help maintain the material’s durable qualities, even in harsh conditions.

UV resistance plays a major role in durability. Sunlight can cause vinyl to fade, yellow, or become brittle. Manufacturers add UV stabilizers and absorbers, such as Titanium Dioxide, to white PVC roll. These additives protect the surface from chalkiness, cracking, and loss of mechanical strength. UV-resistant vinyl maintains its color and structure, reducing maintenance costs and supporting long-term usage. You should inspect your white PVC roll regularly for cracks or fading and clean it with mild soap and water. For outdoor use, seal seams and edges to prevent moisture infiltration.

Tip: Apply a UV-resistant coating and perform routine inspections to maximize the lifespan of your white PVC roll, especially for long-term display or high-traffic areas.

White PVC roll provides a smooth, bright surface that supports vibrant graphics and sharp details. You can use digital UV printing, screen printing, and vinyl application methods. The low-gloss satin finish of expanded PVC foam board enables accurate color reproduction and strong adhesion for vinyl graphics. This makes white PVC roll ideal for high-end signage, retail displays, and exhibition graphics.

Printing Method | Surface Finish | Color Quality | Recommended Use Cases |

|---|---|---|---|

Digital UV Printing | Satin, smooth | Exceptional | Signs, displays, kiosks |

Screen Printing | Satin, smooth | Vibrant, sharp | POP/POS displays, exhibition panels |

Vinyl Application | Smooth | Accurate | Retail graphics, long-term display |

To maintain appearance and print quality, you should clean the surface with a soft microfiber cloth and mild detergent. Avoid abrasive cleaners and harsh chemicals. Protect printed graphics from direct sunlight with UV protective films or coatings. Regular sweeping and vacuuming with soft tools prevent scratches and preserve the durable finish. Select vinyl with superior abrasion resistance for high-traffic areas to ensure your graphics stay bright and clear.

Regular cleaning and proper installation help your white PVC roll maintain its durable appearance and print quality over time.

Choosing the best white PVC roll starts with understanding your project’s environment, durability needs, and display method. You should check thickness, finish, and size for your application. For signage, indoor use extends lifespan, while outdoor use limits durability to about two years. Suppliers can help you get custom sizes and expert advice on fabrication and mounting.

Match your project needs to the right white PVC roll and adhesive. Consult with professionals to ensure clean edges and proper finishes. Make confident decisions for long-lasting results.

Selection Criterion | Why It Matters |

|---|---|

Intended Use Environment | Affects lifespan and material choice |

Thickness & Size | Ensures rigidity and proper fit |

Finish | Impacts visibility and readability |

You can use a White PVC Roll for signs, displays, insulation, and protective coverings. Many industries choose it for its durability, moisture resistance, and easy fabrication. It works well indoors and outdoors.

You can cut a White PVC Roll with a utility knife, scissors, or a saw, depending on thickness. Always use a straight edge for clean lines. Wear gloves for safety.

Yes, you can print directly on a White PVC Roll. Digital UV printing and screen printing both work well. The smooth surface helps graphics look sharp and vibrant.

White PVC Roll resists moisture, UV rays, and most chemicals. You can use it outdoors for signs and coverings. For long-term outdoor use, choose rolls with UV stabilizers.

Select thickness based on your project. Thin rolls suit crafts and displays. Thick rolls provide strength for construction or industrial use. Ask your supplier for advice if unsure.