Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

When you choose a white PVC roll, you select a flexible plastic sheet made from polyvinyl chloride. This material stands out for its strength, chemical resistance, and simple installation. You often see white PVC in construction, signage, and manufacturing because it stays clean and resists stains. The white color signals purity, making it ideal for potable water and sanitary environments. In recent years, demand for white PVC and pvc plastic sheet rolls has risen sharply, especially as polyvinyl and poly-vinyl-chloride products support rapid growth in global infrastructure. PVC plastic sheet rolls offer versatility and reliability for many industries.

White PVC rolls are strong, flexible plastic sheets that resist chemicals, stains, and wear, making them durable for many uses.

The white color signals cleanliness and purity, ideal for water systems, cleanrooms, and food processing where hygiene matters.

White PVC is easy to shape, cut, and print on, which makes it popular for construction, signage, manufacturing, flooring, and electrical work.

Proper care like using UV protection and gentle cleaning helps white PVC last longer outdoors without yellowing or damage.

Compared to other plastics, white PVC offers a good balance of cost, strength, and chemical resistance, making it a smart choice for many projects.

When you look at a white PVC roll, you see a product made from polyvinyl chloride. Manufacturers use high-purity polyvinyl chloride resin as the base. They add plasticizers, stabilizers, fillers, lubricants, pigments, and other additives to improve the properties of the pvc plastic sheet rolls. The purity and consistency of these raw materials matter a lot. Impurities can lower the quality and performance of the white pvc sheet.

Raw Material | Role in Production and Effect on Product Quality |

|---|---|

Polyvinyl Chloride Resin | Forms the base material; quality affects uniformity, stability, chemical resistance, weathering resistance, and mechanical strength. |

Plasticizers | Used in small amounts to influence flexibility and workability; choice affects rigidity and environmental compliance. |

Stabilizers | Prevent degradation from heat, light, and chemicals; maintain physical and chemical properties over time; types include lead-free options. |

Fillers (e.g., Calcium Carbonate) | Improve stiffness, dimensional stability, heat resistance; controlled to avoid negative effects on performance. |

Lubricants | Reduce friction during processing; ensure smooth flow and surface finish; types include internal and external lubricants. |

Pigments (e.g., Titanium Dioxide) | Provide white color; affect heat stability and lightfastness; choice depends on application and environmental exposure. |

Impact Modifiers | Enhance toughness and impact resistance; important for applications requiring high impact strength. |

Antioxidants | Prevent oxidation during processing and use; extend product life by maintaining mechanical properties and color. |

UV Absorbers | Protect against UV degradation; prevent discoloration and embrittlement; extend outdoor service life. |

The molecular structure of polyvinyl chloride gives white pvc rolls their flexibility. The chains in polyvinyl contain chlorine atoms, which create strong forces between molecules. When you add plasticizers, these forces weaken, and the chains move more freely. This change makes the white pvc sheet flexible and tough. Without plasticizers, pvc sheet stays rigid.

Tip: The right mix of additives in glossy white pvc plastic sheet ensures you get the best balance of flexibility, strength, and durability for your project.

You can count on white pvc rolls for long-lasting performance. In industrial settings, white pvc sheet and pvc plastic sheet rolls often last for decades. For example, building materials made from white pvc can last over 20 years. PVC water pipes may last more than 50 years. Rigid foam board insulation can last 100 years or more. These numbers show the impressive durability of glossy white pvc plastic sheet.

PVC Material Type | Typical Lifespan | Wear Resistance / Durability Characteristics |

|---|---|---|

Building PVC materials | Over 20 years | Excellent longevity, corrosion resistance, and durability |

PVC water pipes | More than 50 years | Operational longevity in harsh environments |

PVC foam boards | Up to 40 years | Moisture and corrosion resistant, good wear resistance and strength |

Rigid foam board insulation | 100 years or more | Firmness, water resistance, and long-term durability |

PVC foams (e.g., gaskets) | Long product life (decades) | Wear resistance and strength suitable for industrial sealing applications |

White pvc rolls also perform well in accelerated aging tests. Even after weeks of exposure to heat and humidity, glossy white pvc plastic sheet keeps its color and physical properties. The water vapor transmission rate stays stable, which means the material does not break down easily. You can rely on pvc plastic sheet rolls for both indoor and outdoor use.

One of the main features of white pvc is its strong resistance to many chemicals. You can use white pvc sheet in places where it will contact water, acids, and many cleaning agents. The material does not dissolve in water and resists corrosion.

Aspect | Details |

|---|---|

Chemicals white PVC rolls resist | Resistant to water due to insolubility in water. |

Chemicals white PVC rolls not resistant to | Many organic solvents including tetrahydrofuran (THF), dimethylformamide (DMF), dimethylacetamide (DMA), pyridine. |

Limitations of resistance | - Thermal degradation starts visibly at 135 °C, with complete decomposition near 200 °C due to hydrogen chloride release. |

Usable temperature range for pure PVC: −10 to +60 °C; stabilized PVC: −30 to +100 °C.

Degradation caused by thermal dehydrochlorination, UV radiation, oxidation, leading to chemical and physical aging, yellowing, and polymer breakdown.

Environmental exposure causes further degradation and release of harmful chlorinated compounds.

Resistance influenced by additives and stabilizers.

PVC undergoes nucleophilic substitution and elimination reactions on the polymer surface.

UV exposure causes free radical formation, chain cleavage, and photo-oxidation.

PVC degradation contributes significantly to environmental pollution with dioxins.

Compared to other plastics like ABS or polyethylene, white pvc usually offers better chemical resistance. You can expect glossy white pvc plastic sheet to handle harsh environments where other plastics might fail. However, you should avoid exposing pvc sheet to strong organic solvents or very high temperatures.

White pvc rolls stand out for their clean, bright look. The white color comes from pigments like titanium dioxide, which also help with heat stability and lightfastness. You can find glossy white pvc plastic sheet in many finishes, such as matte, smooth, or high-gloss. These finishes make the material suitable for printing, signage, and decorative uses.

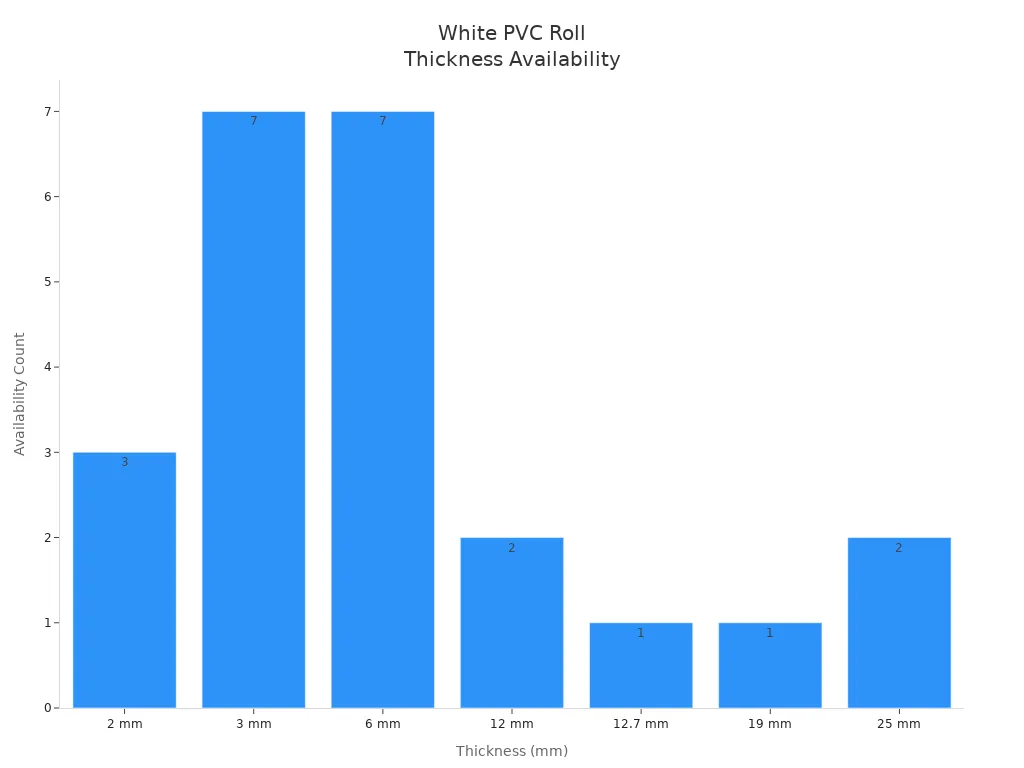

White pvc sheet comes in a wide range of thicknesses, from 1mm up to 30mm, depending on the brand. You can choose from standard white, bright white, and even custom shades. The smooth, non-porous surface of glossy white pvc plastic sheet makes cleaning easy. This is why you often see white pvc in cleanrooms, hospitals, and food processing areas.

Note: The white color of pvc sheet is not just for looks. It signals cleanliness and meets strict hygiene standards. In potable water and cleanroom applications, the white color helps you spot dirt or contamination quickly. The non-porous surface of glossy white pvc plastic sheet prevents dust and microbes from sticking, making it easy to disinfect.

The features of white pvc make it a smart choice for many industries. You get durability, chemical resistance, and a clean appearance all in one material. When you need a reliable, easy-to-clean surface, white pvc rolls and pvc plastic sheet rolls deliver clear benefits.

White pvc rolls have become essential in many industries because of their versatility, durability, and ease of use. You will find white pvc in a wide range of applications, from construction and building industry projects to signage, manufacturing, flooring, and electrical systems. Let’s explore the common uses of white pvc and see why this material stands out.

You see white pvc rolls everywhere in the construction and building industry. Builders use white pvc for plumbing pipes, vinyl siding, window frames, roofing membranes, and wall claddings. These uses help create structures that last and require little maintenance.

Plumbing pipes made from white pvc resist corrosion and chemical damage, ensuring safe water delivery.

Vinyl siding provides weather resistance and insulation, keeping homes comfortable year-round.

Window frames made of white pvc offer energy efficiency, durability, and low maintenance.

Roofing materials use white pvc for waterproofing membranes, which reflect sunlight and reduce heat absorption.

Wall claddings and ceiling films made from white pvc help maintain clean, sanitary environments.

White pvc rolls must meet strict performance standards in construction. You need fire-retardant materials that comply with safety codes. UV stabilizers protect white pvc from sunlight and weather damage. Impact resistance ensures that sheets do not crack or break easily. Manufacturers control the chemical composition to avoid harmful substances. Quality control follows standards like ASTM, ISO, and NFPA.

White pvc roofing membranes help lower energy costs by reflecting sunlight and keeping buildings cooler. Their waterproofing and insulating properties prevent moisture infiltration and maintain temperature control, which supports sustainability and energy efficiency.

White pvc rolls are popular in signage because they are lightweight, affordable, and easy to shape. You can cut white pvc into custom forms for display boards, promotional signs, trade show displays, and even clock faces. The smooth surface of white pvc allows for sharp, high-quality printing.

Material | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

White PVC Rolls | Lightweight, affordable, easy to cut, moisture and chemical resistant, durable, smooth surface for printing | Less durable than acrylic for long-term outdoor use | Promotional signage, trade show displays, wall-mounted signs, indoor or short-term outdoor signage |

Acrylic | High clarity, UV resistance, polished look, scratch-resistant, durable | More expensive, prone to scratching, heavier | Outdoor signage needing clarity and polished appearance |

Metal | Durable, weather resistant, strong | Heavier, more expensive, less customizable | Long-term outdoor signage needing high durability |

White pvc rolls support vibrant, long-lasting prints that resist fading and scratches. ISO4892 certification ensures UV resistance, so your outdoor signs maintain color for years. You can use inkjet, laser, UV digital, and screen printing on white pvc, making it easy to create clear graphics. Self-adhesive backing simplifies installation, even in extreme temperatures.

Tip: Choose white pvc for indoor signs or short-term outdoor displays. You get easy cleaning, moisture resistance, and sharp graphics at a lower cost than acrylic or metal.

Manufacturers rely on white pvc rolls for many processes. You can use pvc sheet forming, vacuum forming, CNC machining, bending, molding, engraving, and roll forming to create shields, cases, pipes, fittings, rollers, bushings, gears, insulators, and safety boards.

White pvc offers excellent structural integrity, chemical resistance, and moisture protection. Its insulating properties and impact strength make it ideal for products like semiconductor components, bearings, and enclosures. You benefit from non-toxicity, fire resistance, and corrosion resistance, which help produce safe and durable items.

CNC machining with white pvc rolls increases production speed and efficiency. You need corrosion-resistant cutting tools and proper setup to maintain tool integrity and product quality.

Vacuum forming lets you create seamless hollow products, such as bottles and shells, with white pvc.

Expanded pvc machining supports engraving and compression molding for custom designs.

Note: White pvc rolls improve manufacturing efficiency because they are easy to shape, cut, and weld. You get durable parts with consistent quality, which reduces waste and lowers costs.

White pvc rolls are a top choice for flooring in healthcare, food processing, and commercial spaces. You see pvc sheet floors in hospitals, kitchens, clean rooms, and laboratories because they offer slip resistance, hygiene, and durability.

Key Reason | Explanation |

|---|---|

Material Quality | White pvc indicates purity and uniformity, which ensures long-lasting performance. |

Antibacterial Properties | Silver-ion treatment achieves high antibacterial rates, crucial for healthcare and food processing. |

Surface Treatment | Embossed texture provides slip resistance and easy cleaning, supporting safety and hygiene. |

Craftsmanship | Multi-layer co-extrusion enhances service life and weld seam strength. |

Compliance and Testing | Strict thickness and wear resistance standards ensure suitability for sensitive environments. |

White pvc flooring is waterproof, stain-resistant, and easy to clean. You avoid problems like trapped dirt or moisture, which can occur with carpets or stone floors. The textured surface of white pvc provides good traction, reducing the risk of slips and falls. Compared to wood or stone, pvc flooring offers better hygiene and moisture resistance.

You can install white pvc flooring in areas that require frequent cleaning and strict hygiene, such as hospitals and food processing plants.

The slip-resistant surface helps prevent accidents, making it safer than stone or wood floors.

When you compare white pvc sheet to other plastics, you notice important differences in cost, durability, and performance. White pvc stands out for its balance of affordability and strength. You pay less upfront for white pvc than for engineering plastics like polycarbonate or acrylic. HDPE sheets cost even less and offer strong durability, but white pvc provides better chemical resistance and is easier to shape for many projects.

Material | Price per kg (USD) | Notes |

|---|---|---|

Virgin UPVC | $0.80 - $2.00 | Widely available commodity material |

Polycarbonate | Around $2.80 | Specialist, high-cost material; recycled PC can be $1.60 per kg |

HDPE | Lower than acrylic, PC, ABS | One of the most affordable plastics; price generally lower than acrylic, PC, ABS |

Acrylic | 2-5 times more expensive than HDPE | Offers better scratch resistance but lacks impact strength |

ABS | 2-5 times more expensive than HDPE | Alternative to PC with easier processing and lower cost |

You see white pvc sheet used for both structural and decorative purposes. It resists moisture and chemicals, making it ideal for wall panels, cladding, and signage. ABS and acrylic offer higher impact strength and clarity, but you face higher costs and more complex installation. HDPE is a cost-effective choice for outdoor use, but it does not match the clean appearance of white pvc.

Tip: Choose white pvc sheet when you need a material that is easy to clean, shape, and install. You get reliable performance for indoor and short-term outdoor projects.

You often use white pvc sheet above ground for outdoor signs, wall coverings, and protective panels. Standard pvc resists water and chemicals, but it does not handle UV exposure as well as some alternatives. When exposed to sunlight, untreated white pvc tends to yellow and lose its brightness. UV-coated pvc sheet maintains color and surface hardness much longer, but it can become brittle and costs more.

If you want to extend the life of white pvc outdoors, you should:

Apply UV-resistant coatings to absorb or reflect harmful rays.

Select pvc sheet with UV stabilizers for better sunlight protection.

Install white pvc sheet in shaded areas to reduce direct exposure.

Clean the surface regularly with mild detergent and water.

Inspect for fading, cracking, or brittleness and repair as needed.

You find that lighter colors like white reflect sunlight better, which helps reduce heat absorption and UV damage. HDPE offers better weather resistance and recyclability, but white pvc gives you a cleaner look and easier maintenance. For decorative uses, white pvc remains a popular choice because you can print, engrave, or shape it easily.

Note: You should avoid harsh chemicals when cleaning white pvc sheet. Gentle cleaning helps preserve UV protection and keeps your pvc looking new.

You will notice that white pvc uses special pigments and additives. These help the material stay bright and clean. White pvc also meets strict standards for hygiene. You often see it in places where cleanliness matters most.

You can use white pvc outdoors for signs, panels, and coverings. Make sure you choose pvc with UV protection. This helps prevent yellowing and brittleness. Regular cleaning keeps your white pvc looking new in outdoor environments.

You can trust white pvc in food and water systems. Manufacturers design white pvc to resist chemicals and bacteria. The smooth surface makes cleaning easy. Many industries use white pvc for potable water pipes and food processing areas.

You should clean white pvc with mild soap and water. Avoid harsh chemicals that can damage the surface. Regular cleaning keeps your pvc bright and free from stains. This helps maintain hygiene in kitchens, hospitals, and labs.

You will find white pvc in wall claddings, pipes, window frames, and roofing. Builders choose white pvc for its durability and easy installation. The material resists moisture and chemicals. White pvc helps create safe, long-lasting structures.