Views: 0 Author: Site Editor Publish Time: 2025-08-25 Origin: Site

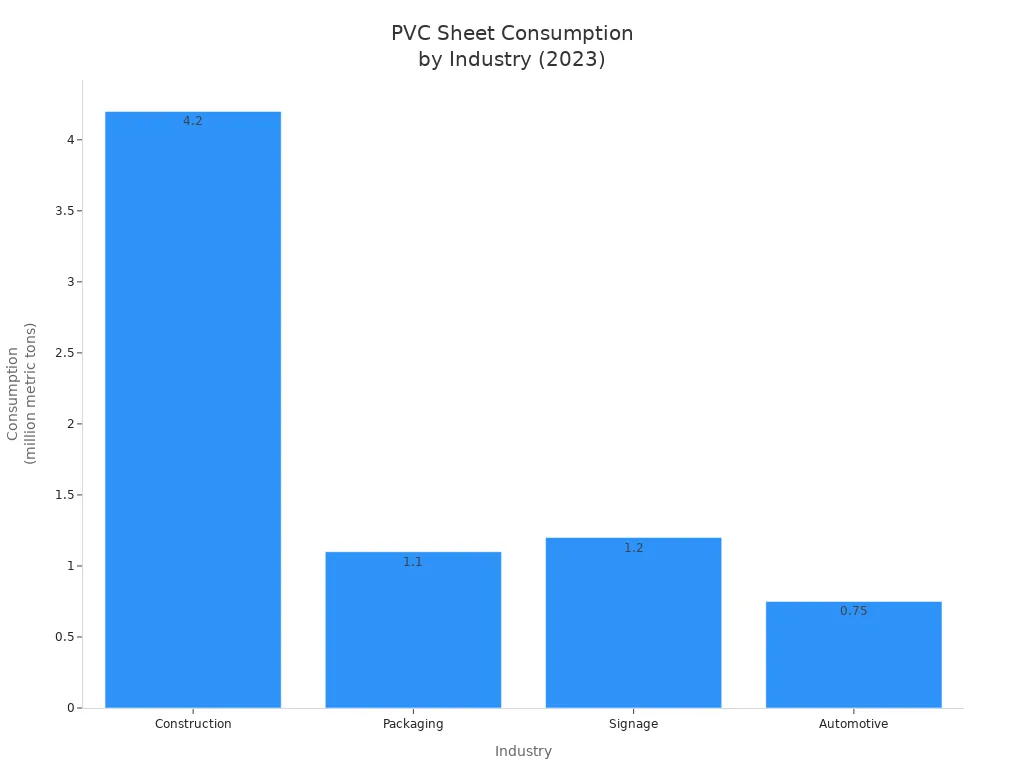

A white PVC sheet is a flat panel made from polyvinyl chloride, a strong plastic with a smooth, white finish. You can find white PVC sheet used in construction, signage, and decoration because it resists chemicals and stays durable over time. Polyvinyl chloride offers a lightweight structure that handles indoor and outdoor environments well. Many industries rely on PVC for its flexibility and easy fabrication. The construction sector uses the most polyvinyl chloride sheets, followed by signage and packaging.

White PVC sheet is a strong, lightweight plastic panel with a smooth white surface, ideal for indoor and outdoor use.

Two main types exist: Expanded PVC, which is lightweight and easy to shape, and Rigid PVC, which offers high chemical resistance and durability.

PVC sheets resist moisture, chemicals, and wear, making them perfect for construction, signage, fabrication, and creative projects.

You can cut white PVC sheets using tools like utility knives for thin sheets and saws or jigsaws for thicker or detailed cuts; always use sharp blades and proper support.

White PVC sheets are easy to clean, cost-effective, and versatile, making them a smart choice for many industries and DIY projects.

You encounter white PVC sheet as a flat, rigid panel made from polyvinyl chloride. Manufacturers blend PVC resin with additives like stabilizers, lubricants, pigments, and plasticizers. These ingredients give the sheet its flexibility, fire resistance, and durability. Polyvinyl chloride contains ethylene and chlorine, with chlorine making up more than half of its mass. This composition gives PVC plastic sheets their strength and resistance to chemicals. You notice that white PVC sheet stands out for its smooth, white surface and consistent thickness.

White PVC sheet does not differ chemically from other PVC variants except for the color pigments and additives used to achieve the white finish. You find the same base elements—carbon, hydrogen, and chlorine—in all polyvinyl chloride products. The sheet’s structure makes it suitable for many applications, including construction, signage, and displays.

Tip: If you need a material that resists moisture and chemicals, white PVC sheet offers reliable performance in both indoor and outdoor environments.

You discover several common types of white PVC sheets available for different applications. The two main types are Expanded PVC and Rigid PVC Type 1. Expanded PVC sheets feature a closed-cell inner core, making them lightweight and easy to handle. These sheets have a smooth matte finish, which works well for painting, laminating, and graphic overlays. You often see expanded PVC used for signage, exhibits, and displays because it is simple to cut and shape.

Rigid PVC Type 1 sheets provide maximum chemical resistance and durability. You choose these sheets for environments where exposure to harsh substances is likely. Both types of white PVC sheet come in various sizes and thicknesses, allowing you to select the best option for your project.

Here is a quick comparison table to help you understand the differences:

Type | Finish | Key Features | Common Applications |

|---|---|---|---|

Expanded PVC | Smooth matte | Lightweight, easy to shape | Signage, displays, exhibits |

Rigid PVC Type 1 | Smooth, hygienic | High chemical resistance, durable | Wall cladding, tanks, fabrication |

You find that white PVC sheet is more affordable than acrylic or polycarbonate sheets. PVC offers cost-effectiveness and versatility, making it a popular choice for many industries. You should consider long-term value, including maintenance and lifespan, when selecting materials for your applications.

Expanded PVC sheets are lightweight and durable.

Rigid PVC sheets offer excellent chemical resistance.

Both types support a wide range of applications, from signage to fabrication.

Note: White PVC sheet is available in many sizes and thicknesses, so you can match the material to your specific needs.

You can rely on pvc foam for impressive durability in demanding environments. Manufacturers test white pvc foam sheets using static tensile testing and dynamic cyclic loading. These tests measure how the material handles stretching, pulling, and repeated stress. For example, engineers use a universal hydraulic machine and optical extensometry to check tensile strength and elongation. After 150,000 cycles of mechanical stress, microscopic examinations show that pvc foam maintains its structure and performance characteristics. This means you get a material that resists cracking, breaking, and fatigue, even after long-term use. Marine-grade pvc foam also stands up to harsh conditions, making it a smart choice for outdoor and marine applications.

Pvc foam sheets offer strong resistance to many chemicals, which makes them suitable for industrial and laboratory settings. You can use pvc foam around alcohols, fats, oils, inorganic acids, alkalis, and salts without worrying about damage. The material also resists chemicals like acetylene, ammonia, and antifreeze. However, you should avoid exposing pvc foam to solvents such as acetone, xylene, or methyl ethyl ketone, as these can cause swelling or permanent changes. High temperatures and strong oxidizers may also reduce chemical resistance. For best performance, always test pvc foam in your specific environment, especially if you need fda compliance or plan to use it with concentrated chemicals.

You have several surface finish options when choosing pvc foam sheets. The most common finishes include smooth, matte, textured, and high gloss. Each finish affects performance and appearance:

Surface Finish | Appearance | Performance Effects | Typical Applications |

|---|---|---|---|

Smooth | Clean, uniform | Easy to print, easy to clean, resists stains | Signage, displays |

Matte | Non-reflective, soft | Reduces glare, hides scratches | Interior design, furniture |

Textured | Tactile, dimensional | Hides imperfections, slip-resistant | Wall panels, cabinetry |

High Gloss | Shiny, reflective | Enhances graphics, shows fingerprints | Promotional signage |

Smooth and matte finishes are popular for indoor use because they are easy to fabricate and maintain. Marine-grade pvc foam often features textured surfaces for slip resistance and durability.

You can use pvc foam sheets both indoors and outdoors, but you should select the right thickness and grade for your project. For indoor applications, 1-5 mm thick sheets work well for signage, displays, and crafts. These sheets are lightweight, easy to fabricate, and moisture-resistant. For outdoor or marine use, choose marine-grade pvc foam in thicknesses from 11-30 mm. These robust sheets resist weather, UV rays, and water, making them waterproof and moisture-resistant. Black pvc sheets last longer outdoors because carbon black protects against UV damage, while white pvc foam reflects light but offers only moderate UV protection. Always check for fda approval if you need the material for food contact or medical use. Pvc foam sheets remain easy to fabricate, cost-effective, and reliable for a wide range of performance characteristics.

Tip: Select marine-grade pvc foam for the best performance in wet or harsh outdoor environments.

White PVC sheet stands out as one of the most versatile materials across many industries. You will find it in construction, advertising, fabrication, interior design, and creative projects. Its unique properties—such as being lightweight, moisture-resistant, and easy to fabricate—make it a top choice for a wide range of applications.

You often see white PVC sheet used in construction applications because it offers several advantages over traditional materials. Here are some reasons why you might choose it for your next project:

PVC foam resists scratches, dents, and moisture damage.

It does not warp or swell, even in humid environments.

Cleaning is simple; you only need mild soap and water.

The material resists chemicals found in most homes.

You can shape, cut, and install it easily due to its lightweight nature.

PVC foam provides excellent sound and thermal insulation.

It is flame retardant and moisture-proof, making it ideal for wet or humid areas.

The lightweight structure reduces transportation costs and simplifies installation.

You can use white PVC sheet for wall cladding, partitions, ceilings, and even as a backing for cabinets. Its durability and low maintenance make it a smart choice for both residential and commercial construction.

Tip: PVC foam boards help you avoid problems like rotting, rusting, and fading that affect wood, metal, or concrete.

White PVC sheet is a favorite for signage and display applications. You benefit from its smooth, bright surface, which is perfect for printing high-quality graphics. The material is lightweight and easy to fabricate, so you can cut, shape, and mount it without special tools.

The smooth finish allows for vibrant, sharp visuals.

PVC foam resists water, chemicals, and UV rays, so your signs last longer outdoors.

You can clean the surface easily, keeping your displays looking professional.

The rigid structure prevents warping and bending, even in large panels.

Printing on white PVC sheet works well with digital printing, screen printing, and UV printing. The white color enhances the impact of your designs, making them stand out in any setting.

Printing Technique | Compatibility with White PVC Sheet | Benefits |

|---|---|---|

Digital Printing | Excellent | Fast, precise, great for small batches |

Screen Printing | Excellent | Bold, vibrant colors, ideal for banners |

UV Printing | Excellent | Fade-resistant, vivid colors, outdoor use |

Offset Printing | Good | Consistent quality for high-volume runs |

Laser Engraving | Good | Custom shapes and detailed graphics |

You can also use white PVC sheet for card substrate, such as business cards, loyalty cards, and ID cards. The material’s smooth, flat surface ensures sharp, clear printing, while its durability means your cards resist bending, moisture, and fading. PVC foam is easy to fabricate into precise shapes and sizes, making it ideal for custom card production.

Note: High-resolution UV printing on white PVC sheet ensures your business cards and displays maintain their professional appearance over time.

You will find white PVC sheet in many fabrication applications, especially for tanks, valves, and piping systems. PVC foam is easy to fabricate, weld, and machine, which helps you create custom devices and structures for industrial use.

The material resists acids, alkalis, and other harsh chemicals.

It prevents corrosion and degradation, even in wet environments.

PVC foam has low moisture absorption, making it suitable for tanks and containers.

Fire resistance adds an extra layer of safety in hazardous settings.

Safety Consideration | Details |

|---|---|

Chemical Exposure Warning | PVC contains polyvinyl chloride, which may pose health risks. Check local regulations for safe use. |

Fabrication Responsibility | Always verify material suitability and test for your specific application. |

Operating Temperature Limits | Use up to 140°F; heat deflection at 158°F under pressure. |

Fire Safety | Excellent fire rating (UL-94 V-0); low flame spread. |

Material Composition | Rigid PVC Type 1, no plasticizers or fillers, suitable for self-supporting construction. |

PVC foam’s chemical resistance and easy fabrication make it a reliable choice for industrial tanks and custom devices.

You can use white PVC sheet for trim, moldings, and wall panels in both homes and commercial spaces. PVC foam is lightweight, moisture-proof, and easy to fabricate, so you can install it quickly and maintain it with minimal effort.

Common uses include window and door surrounds, fascia, soffit trim, deck skirting, and porch ceilings.

You can also use it for shiplap, tongue & groove wall paneling, and corner boards.

The smooth, bright surface is easy to clean and resists scratches.

PVC foam panels are waterproof and mold-free, making them ideal for bathrooms, kitchens, and laundry rooms.

PVC wall panels often feature interlocking systems and hidden fasteners, which help prevent moisture infiltration and maintain a seamless look. You can install them directly over tiles or drywall, saving time and labor.

Note: Many PVC foam panels are FDA and USDA approved, so you can use them in commercial kitchens and other hygienic environments.

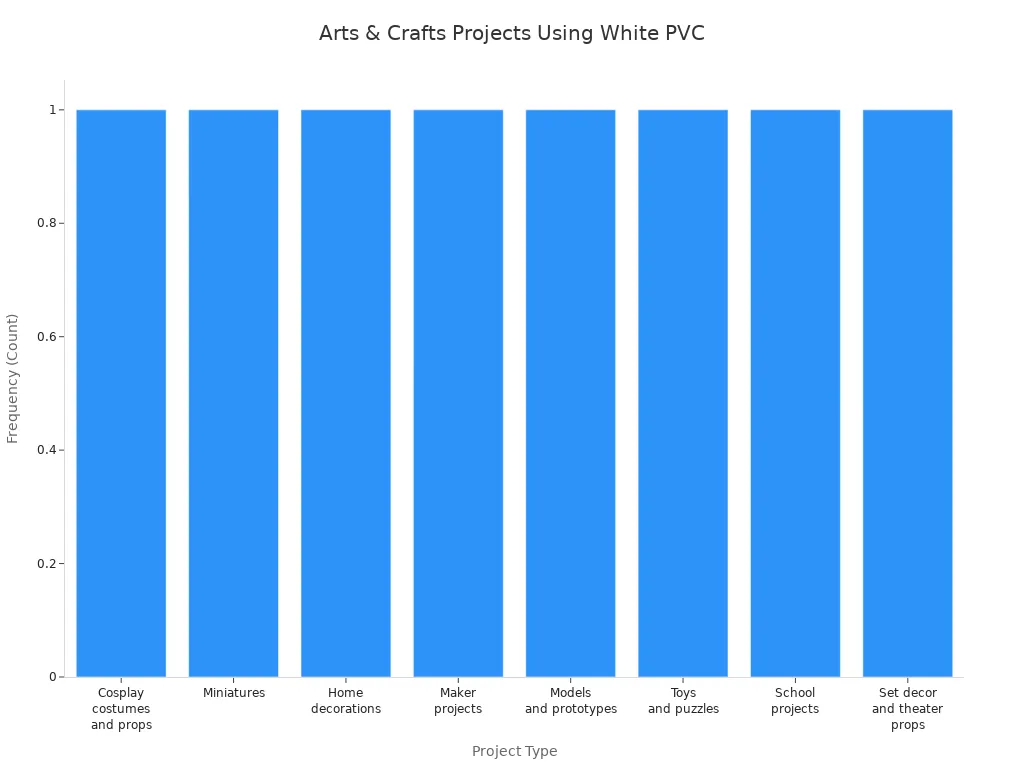

White PVC sheet opens up endless possibilities for creative projects. You can cut, bend, paint, and shape PVC foam for a variety of arts and crafts applications.

Project Types Using White PVC Sheets | Supporting Details |

|---|---|

Cosplay costumes and props | Lightweight, easy to fabricate and thermoform, suitable for detailed costume parts |

Miniatures | Excellent structural properties, durable yet easy to bend |

Home decorations | Versatile and paintable surface for creative designs |

Maker projects | Easily cut and drilled, ideal for DIY and prototyping |

Models and prototypes | Durable, can be screwed and shaped for architectural or design models |

Toys and puzzles | Safe, lightweight, and customizable for children’s crafts |

School projects | Easy to work with conventional tools, suitable for educational crafts |

Set decor and theater props | Waterproof and chemical resistant, ideal for stage use |

PVC foam is a popular choice for cosplay, models, and maker projects because it is easy to fabricate and holds its shape well. You can use simple tools to cut and drill the material, and its paintable surface lets you create custom designs. For school projects and toys, PVC foam is safe, lightweight, and durable.

Tip: Upcycling white PVC sheet in creative projects can reduce environmental impact and give new life to leftover materials.

If you want a material that is easy to fabricate, moisture-resistant, and suitable for a wide range of applications, white PVC sheet is an excellent choice. The common uses of pvc foam span from construction to creative arts, making it one of the most adaptable materials available.

Cutting white PVC sheets requires the right tools and careful technique to achieve clean, smooth edges. You can choose from several methods depending on the thickness of the sheet and the type of cut you need.

You have many options when selecting tools to cut white PVC sheets. The best tool depends on the thickness and complexity of your project. Here is a comparison of popular tools:

Tool Name | Key Features and Pros | Limitations and Cons |

|---|---|---|

GARTOL Miter Shears | Sharp blades for clean cuts; ergonomic handle; safety lock | Not for thick materials; blades dull faster |

Ronan Multi-Cut 401 | Cuts thick materials; extra blades; comfortable handle | Safety lock tricky; higher price; bulky size |

WORKPRO Cordless Scissors | Fast cutting; cordless; non-slip grip | Noisy; limited battery; safety start buttons |

For thin sheets (under 5mm), you can use a sharp utility knife or fine-tooth hand saw. For thicker sheets, a table saw with a 10-inch blade (60-80 teeth, triple-chip design) or a circular saw with a carbide-tipped blade works well. If you need to make curves or intricate shapes, a jigsaw is a good choice. For professional results, CNC machines or water jet cutting provide high precision.

Tip: Always use sharp blades or cutters. Dull tools can cause rough edges, chipping, or melting.

You can achieve the best results by following these tips:

Mark your cut line clearly with masking tape or a pencil.

Clamp the PVC sheet securely and support it with wood underneath to prevent chipping.

For thin sheets, score along the line several times with a utility knife, then snap the sheet cleanly.

For thicker sheets, use slow, steady pressure with a power saw to avoid melting or rough edges.

Sand the edges with fine-grit sandpaper (220–400 grit) after cutting to remove burrs and achieve a smooth finish.

Wear safety goggles and gloves to protect yourself from debris and sharp edges.

Work in a well-ventilated area, especially when using power tools that create dust or fumes.

Follow all manufacturer instructions for your tools and keep them in good condition.

You can minimize waste by making multiple light passes with your knife or saw, rather than forcing a single deep cut. For large or complex projects, consider professional cutting services to ensure precise, clean edges.

Note: The quality of your tools and your cutting technique directly affect the finish and durability of your white PVC sheet edges.

White PVC sheet gives you a cost-effective, durable, and versatile solution for many industries. You benefit from its lightweight structure, waterproof surface, and strong chemical resistance. Common uses include construction, signage, and for card substrate in advertising. You can easily cut, shape, and install it for projects at home or work.

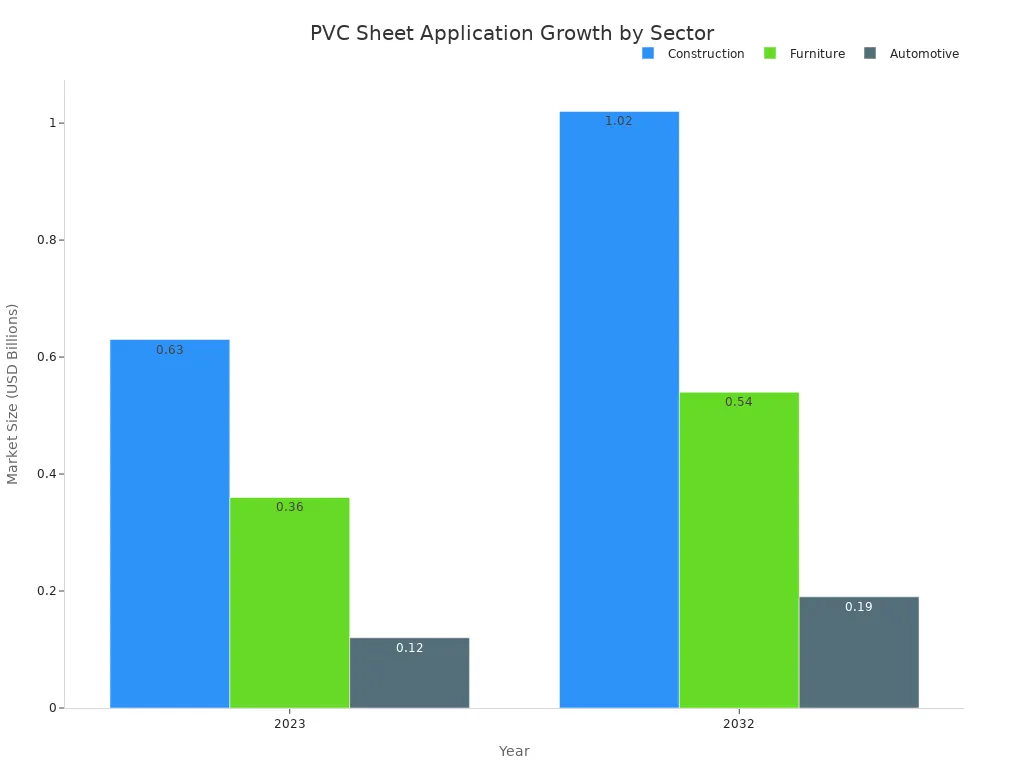

White PVC sheet adapts to new trends in furniture, automotive, and construction. You see steady market growth and more eco-friendly options every year.

Consider white PVC sheet for your next project if you want reliable performance and easy customization.

You can use a White PVC Sheet in construction, signage, displays, and even for card substrate. Its smooth surface and durability make it ideal for printing, cutting, and shaping in many industries.

Yes, you can use White PVC Sheet outdoors. It resists moisture, UV rays, and weather. For best results, choose the right thickness and grade for your outdoor project.

You can safely use White PVC Sheet for card substrate. It provides a smooth, printable surface and resists bending, moisture, and fading. Many businesses choose it for loyalty cards, ID cards, and business cards.

You can clean a White PVC Sheet with mild soap and water. Use a soft cloth or sponge. Avoid harsh chemicals or abrasive pads to keep the surface smooth and bright.

You can use a utility knife for thin sheets or a fine-tooth saw for thicker ones. For detailed shapes, try a jigsaw. Always use sharp blades and support the sheet to get clean, smooth edges.